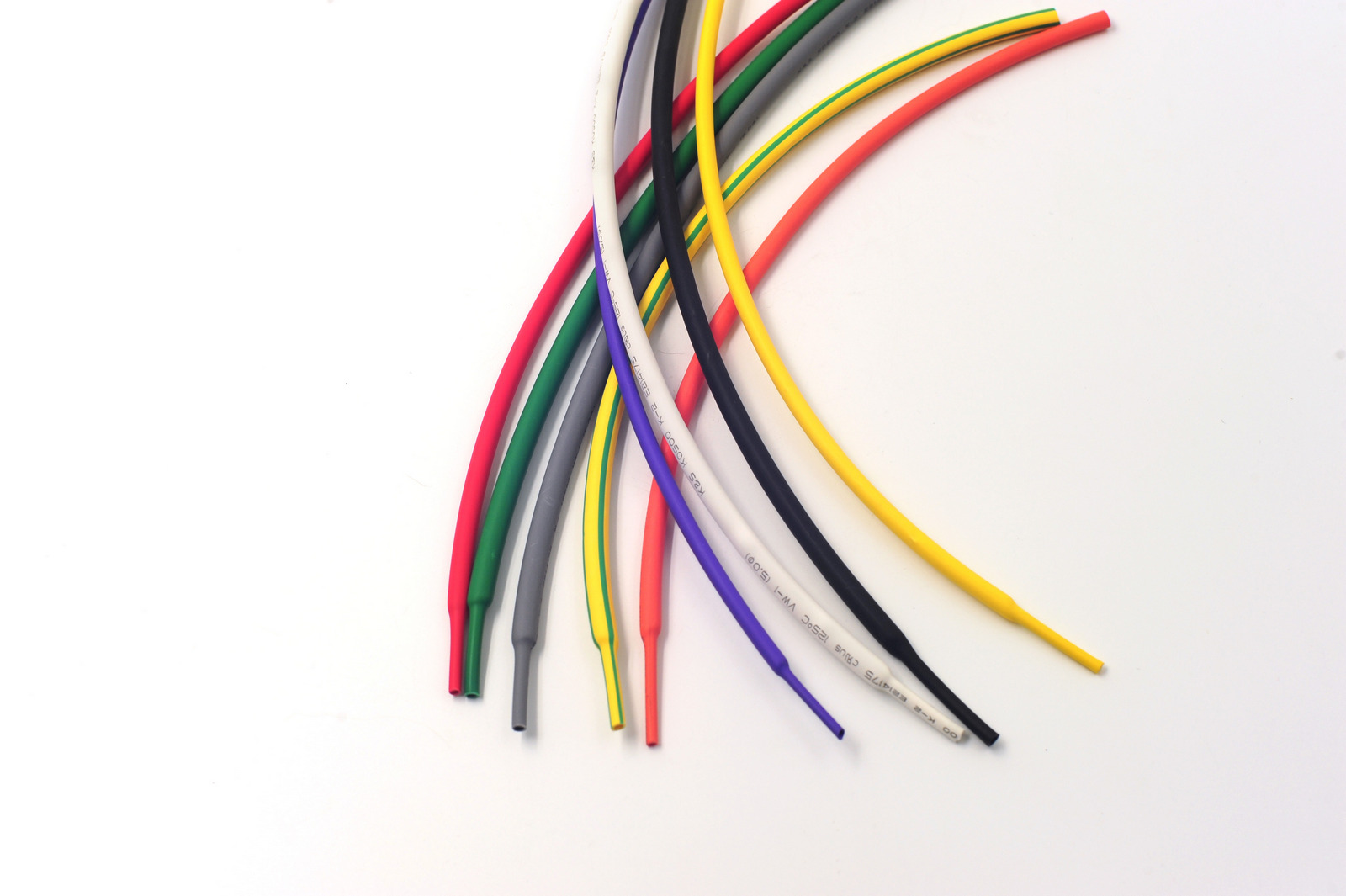

K-2 flame-retardant polyolefin tubing

K-2 flame-retardant polyolefin tubing

·Shrink ratio: 2:1.

·Very flexible, highly flame-retardant.

·Low shrink temperature.

·Good thermal stability.

·Excellent physical, chemical and electrical properties.

·Free of PCBs, PCPs, polybrominated biphenyls (PBBs), polybrominated biphenyl oxides and ethers (PBBOs, PBBEs and PBDEs) and toxic heavy metal compounds, which are classified as environmentally hazardous substances. Conform to European RoHS environmental directive.

·Wide range of sizes and colors.

Operating temperature range: -55℃~125℃

Minimum shrink temperature: 70℃

Minimum full recovery temperature: 110℃

UL224 E214175 125℃ 600V VW-1

AMS-DTL-23053/5 class 2 and class 3

|

|

Property |

Requirement |

Test method |

Typical data |

|

Physical: |

Concentricity |

70% min. |

ASTM D 2671 |

≥70% |

|

|

Tensile strength |

10.4MPa min. |

ASTM D 638 |

≥14.0MPa |

|

|

Elongation |

200% min. |

ASTM D 638 |

≥400% |

|

|

Heat shock 250℃, 4hrs |

No cracking, dripping or flowing |

ASTM D 2671 |

Pass |

|

|

Low temperature flexibility |

No cracking |

ASTM D 2671 |

Pass |

|

Aging 158℃,168hrs |

|

|

|

|

|

Tensile strength after aging |

70% of original min. |

ASTM D 638 |

≥90% |

|

|

Elongation after aging |

100% min. |

ASTM D 638 |

≥300% |

|

|

Electrical: |

Dielectric voltage withstand |

2500V, 60sec no breakdown |

UL224 |

Pass |

|

Dielectric strength |

19.7kV/mm min. |

ASTM D 2671 |

25kV/mm |

|

|

Volume resistivity |

1014Ω·cm min. |

ASTM D 876 |

≥1014Ω·cm |

|

|

Chemical: |

Corrosion |

No corrosion |

ASTM D 2671 |

Pass |

|

|

Flammability |

VW-1 |

UL224 |

Pass |

·Inch size mm/inch

|

Size |

Inside diameter |

Wall thickness |

Standard length (m/spool) |

|

|

As supplied(min.) |

After recovery(max.) |

After recovery |

||

|

3/64 |

1.2(0.046) |

0.6(0.023) |

0.40±0.08(0.016±0.003) |

200 |

|

1/16 |

1.6(0.063) |

0.8(0.031) |

0.43±0.08(0.017±0.003) |

200 |

|

3/32 |

2.4(0.093) |

1.2(0.046) |

0.51±0.08(0.020±0.003) |

200 |

|

1/8 |

3.2(0.125) |

1.6(0.062) |

0.51±0.08(0.020±0.003) |

200 |

|

3/16 |

4.8(0.187) |

2.4(0.093) |

0.51±0.08(0.020±0.003) |

100 |

|

1/4 |

6.4(0.250) |

3.2(0.125) |

0.64±0.08(0.025±0.003) |

100 |

|

3/8 |

9.5(0.375) |

4.8(0.187) |

0.64±0.08(0.025±0.003) |

100 |

|

1/2 |

12.7(0.500) |

6.4(0.250) |

0.64±0.08(0.025±0.003) |

100 |

|

3/4 |

19.1(0.750) |

9.5(0.375) |

0.76±0.08(0.030±0.003) |

50 |

|

1 |

25.4(1.000) |

12.7(0.500) |

0.89±0.12(0.035±0.005) |

50 |

|

1 1/4 |

31.8(1.250) |

15.9(0.625) |

1.02±0.15(0.040±0.006) |

50 |

|

1 1/2 |

38.1(1.500) |

19.1(0.750) |

1.02±0.15(0.040±0.006) |

50 |

|

2 |

50.8(2.000) |

25.4(1.000) |

1.14±0.16(0.045±0.007) |

50 |

·Metric size

|

Size(mm) |

As supplied(mm) |

After recovery (mm) |

Standard length (m/spool) |

||

|

Inside diameter |

Wall thickness |

Inside diameter(max.) |

Wall thickness(min.) |

||

|

Φ0.8 |

1.0±0.2 |

0.15±0.05 |

0.50 |

0.25 |

200 |

|

Φ1.0 |

1.5±0.3 |

0.20±0.05 |

0.60 |

0.33 |

200 |

|

Φ1.5 |

2.0±0.3 |

0.20±0.05 |

0.75 |

0.36 |

200 |

|

Φ2.0 |

2.5±0.3 |

0.20±0.05 |

1.00 |

0.44 |

200 |

|

Φ2.5 |

3.0±0.3 |

0.25±0.05 |

1.25 |

0.44 |

200 |

|

Φ3.0 |

3.5±0.3 |

0.25±0.05 |

1.50 |

0.44 |

200 |

|

Φ3.5 |

4.0±0.3 |

0.25±0.05 |

1.75 |

0.44 |

200 |

|

Φ4.0 |

4.5±0.3 |

0.25±0.05 |

2.00 |

0.44 |

200 |

|

Φ4.5 |

5.0±0.3 |

0.25±0.05 |

2.25 |

0.44 |

200 |

|

Φ5.0 |

5.5±0.3 |

0.28±0.05 |

2.50 |

0.56 |

100 |

|

Φ6.0 |

6.5±0.3 |

0.28±0.05 |

3.00 |

0.56 |

100 |

|

Φ7.0 |

7.6±0.3 |

0.30±0.07 |

3.50 |

0.56 |

100 |

|

Φ8.0 |

8.6±0.3 |

0.30±0.07 |

4.00 |

0.56 |

100 |

|

Φ9.0 |

9.6±0.3 |

0.30±0.07 |

4.50 |

0.56 |

100 |

|

Φ10.0 |

10.7±0.4 |

0.30±0.07 |

5.00 |

0.56 |

100 |

|

Φ11.0 |

11.7±0.4 |

0.30±0.07 |

5.50 |

0.56 |

100 |

|

Φ12.0 |

12.7±0.4 |

0.30±0.07 |

6.00 |

0.56 |

100 |

|

Φ13.0 |

13.7±0.4 |

0.35±0.08 |

6.50 |

0.69 |

100 |

|

Φ14.0 |

14.7±0.4 |

0.35±0.08 |

7.00 |

0.69 |

100 |

|

Φ15.0 |

15.7±0.5 |

0.35±0.08 |

7.50 |

0.69 |

100 |

|

Φ16.0 |

16.7±0.5 |

0.35±0.08 |

8.00 |

0.69 |

100 |

|

Φ18.0 |

19.0±0.5 |

0.40±0.10 |

9.00 |

0.77 |

100 |

|

Φ20.0 |

21.0±0.5 |

0.40±0.10 |

10.00 |

0.77 |

50 |

|

Φ22.0 |

23.0±0.5 |

0.40±0.10 |

11.00 |

0.77 |

50 |

|

Φ25.0 |

26.0±1.0 |

0.45±0.10 |

12.50 |

0.87 |

50 |

|

Φ28.0 |

29.0±1.0 |

0.45±0.10 |

14.00 |

0.87 |

50 |

|

Φ30.0 |

31.5±1.0 |

0.45±0.10 |

15.00 |

0.87 |

50 |

|

Φ35.0 |

36.5±1.0 |

0.50±0.10 |

17.50 |

0.97 |

50 |

|

Φ40.0 |

41.5±1.0 |

0.50±0.10 |

20.00 |

0.97 |

50 |

|

Φ50.0 |

51.5±1.0 |

0.55±0.10 |

25.00 |

0.97 |

50 |

|

Φ60.0 |

63.0±3.0 |

0.60±0.15 |

30.00 |

1.17 |

25 |

|

Φ70.0 |

71.0±3.0 |

0.60±0.15 |

35.00 |

1.17 |

25 |

|

Φ80.0 |

81.0±3.0 |

0.65±0.15 |

40.00 |

1.20 |

25 |

|

Φ90.0 |

91.0±3.0 |

0.75±0.15 |

45.00 |

1.30 |

25 |

|

Φ100 |

101.0±3.0 |

0.75±0.15 |

50.0 |

1.30 |

25 |

|

Φ120 |

121.0±4.0 |

0.80±0.20 |

60.0 |

1.40 |

15 |

|

Φ150 |

151.0±4.0 |

0.80±0.20 |

75.0 |

1.50 |

15 |

|

Φ180 |

181.0±4.0 |

0.85±0.20 |

90.0 |

1.60 |

15 |

Standard: Black (-BK), white (-WH), red (-RD), blue (-BL), yellow (-YL), green (-GR)

Nonstandard: Brown (- BR), orange (-OR), violet (-VT), gray (-GY), yellow & green stripe (-GYS)

Special sizes are available upon request.

On spools. Cut pieces are available upon request.

Specify product type, size (mm or inch) and color.

Tel:+86-20-32079090

Fax:+86-20-32079018

Web:www.gzkaiheng.com

E_mail:angel@gzkaiheng.com

Add:NO.148,Chang'an,Guangshan Road,Huangpu District,Guangzhou,China

Online Service:

National Service Hotline:

86-20-32078038